* DESIGN OF

THE YEAR 2009

Nanyang Optical Co Pte Ltd

Inspired by the Japanese art of origami, the Urband Origami is designed by Nanyang Optical Co Pte Ltd and its Chairman, Yang Wah Kiang. Mr Yang has spent much of his life working with optical technology and in eyewear manufacture and design, and the Urband Origami is a demonstration of his hands-on approach to applying existing technical know-how and technology to the design of innovative eyewear.

Mr Yang describes the target audience for the Urband Origami as “mainly men in their mid- 30s and above”. The intended customer is “someone who likes to wear unique eyewear and appreciates a frame that is constructed with precision engineering. It is similar to someone who appreciates a mechanical watch over a quartz watch.”

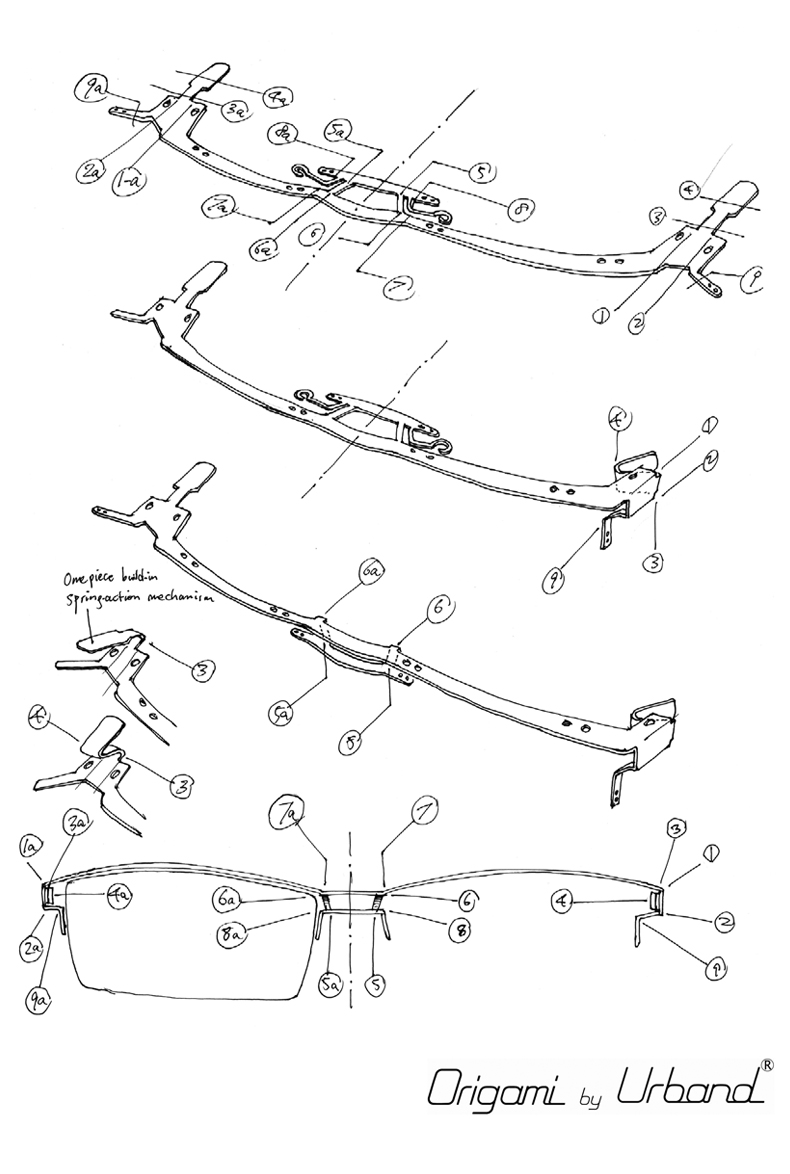

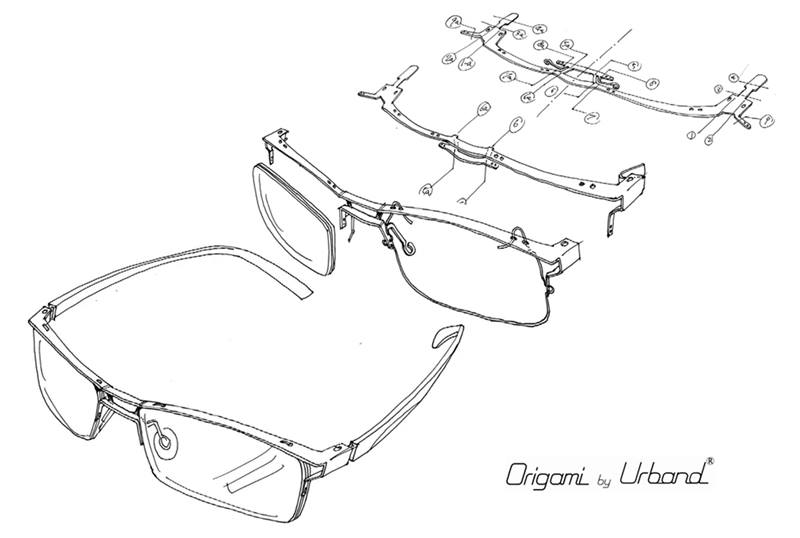

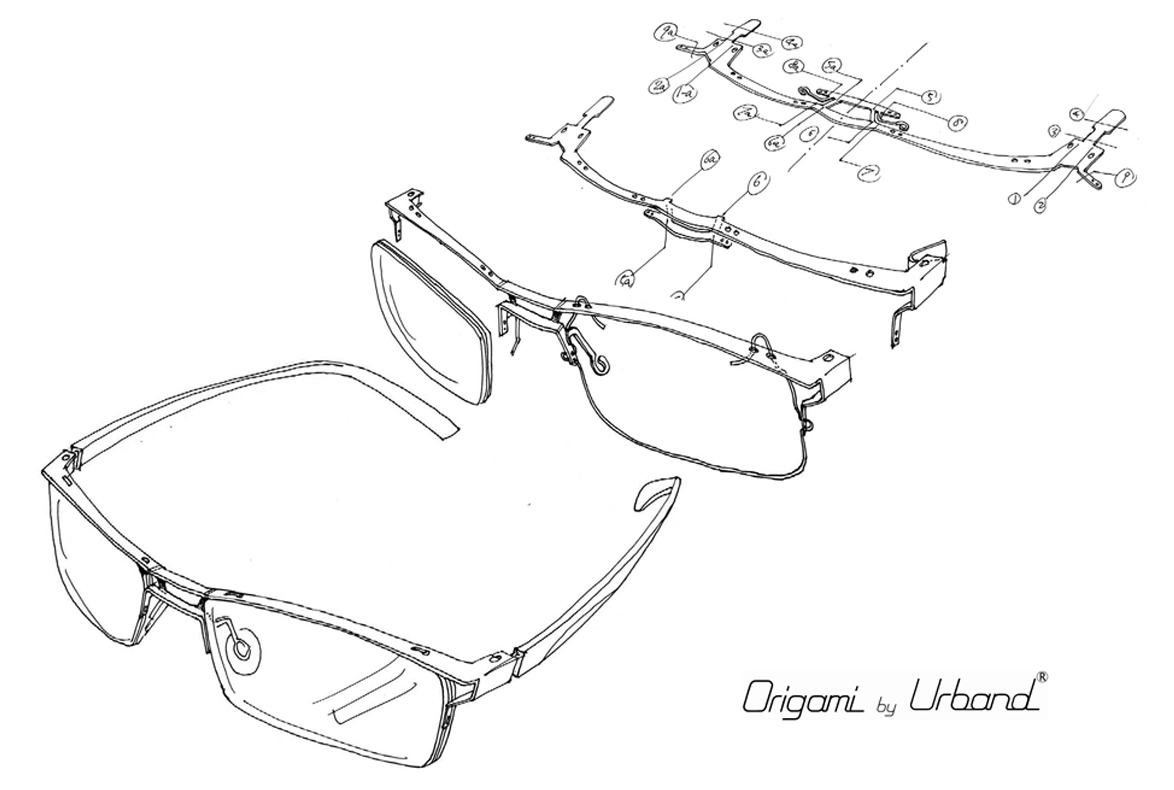

Unlike other brands that are identifiable by their branding, the Urband Origami stands out due to its distinctive frame design and revolutionary production process. In a first for the eyewear design industry, the Urband Origami is created by bending and folding a single stainless steel sheet measuring only 0.4 mm 23 times to form a frame front with multi-function mechanisms. Says Mr Yang, “We have designed and produced Urband Origami eyewear in an innovative way instead of following conventional methods. We strive to be one of the best international eyewear design and R&D companies in the world.”

The design process began with the team at Nanyang Optical putting the design on paper, marking each bending in a process similar to the origami paper-folding process. Says Mr Yang, “For the first prototype model, we experimented with aluminium, which is a softer material that is easier to bend. Once we succeeded with the prototype constructed with aluminium, we proceeded to do moulds for the final design using a stainless steel sheet.”

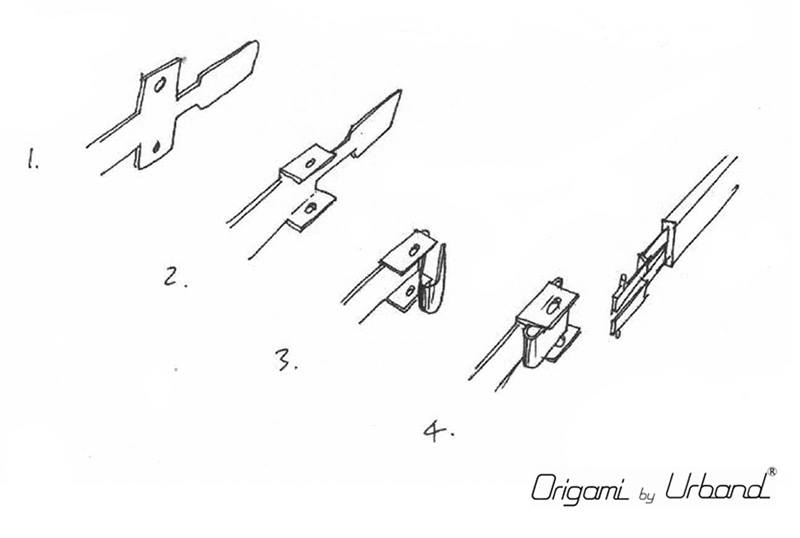

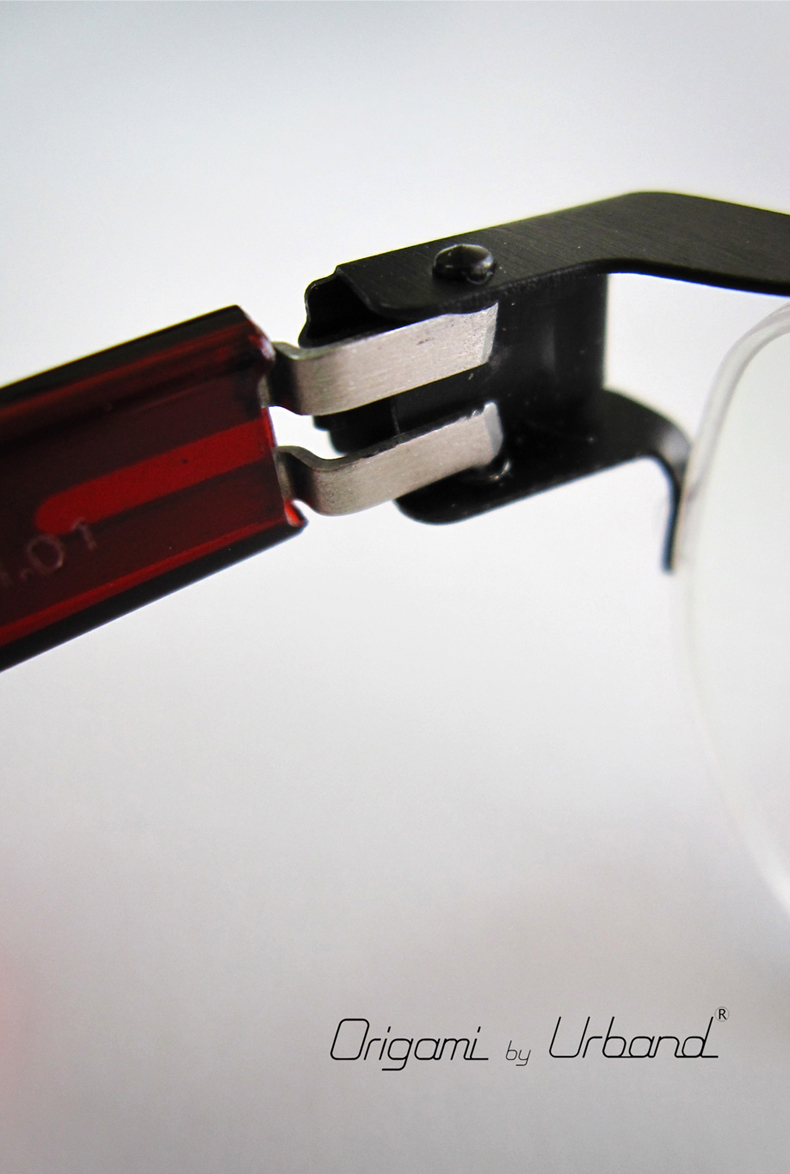

The frame front is made of stainless steel while the temples are made of acetates. The bending process of the sheet metal creates a threedimensional effect with 23 folds, and while it achieves the “block metal” look, the frame retains a lightweight quality. The frame front and S-clip locking devices are cleverly bent into one piece, where the S-clips secure the frame to the temples and create a spring-like effect for wearing comfort. The manufacturing process is also environmentally friendly, requiring no soldering at all. Says Mr Yang, “We believe this innovation is a first in the eyewear design industry.”

This manufacturing process to turn the design into reality is every bit as complex and exacting as it sounds. The greatest challenge lies in achieving accurate alignment for all the bendings on the stainless steel sheet, which requires precision engineering of the highest level. Says Mr Yang, “It is very difficult and challenging to bend and fold a stainless steel sheet into a nice pair of frames. The slightest misalignment can cause defects to the frame. Up till now, we are still facing a high rejection rate in our Origami frames.”

Despite the difficulties, Mr Yang is delighted with the final product. He says, “The most satisfying aspect of this project is the successful creation of the Urband Origami frame, followed by winning several international design awards which provide strong endorsement and recognition of our designs. The most gratifying win of all is the prestigious President’s Design Award 2009 … My team and I feel honoured! At the same time, we are more inspired to explore new challenges in the design and innovation of eyewear.”

READ MORE

ABOUT THE DESIGNER

READ MOREDESIGNERS

Nanyang Optical Co Pte Ltd

Yang Wah Kiang

Zhang Andong

Insights from the Recipient

Citation

Jury Citation

Urband Origami glasses are aesthetically minimalist, technologically ingenious and stylistically “way cool”. The ultra-thin frame is a single strip of 0.4mm-thin laser-cut metal bent in 23 places using sophisticated bending technology. An integrated S-clip mechanism connects the frame to the side pieces to form a strong, flexible, feather-light, highly comfortable ensemble.

Urband Origami is also environmentally friendly in that the manufacturing technique does not require any soldering.

The lead designer, Yang Wah Kiang, has lifelong experience with optical technology and glasses manufacture. Urband Origami is only one of a range of ingeniously designed eyewear that he creates, manufactures and markets.

Not formally trained as a designer, Wah Kiang nevertheless meets the highest standards for original thinking, innovative problem-solving, formal sensibility, and technical understanding. He is single-minded in his pursuit of originality, quality and his goal to advance the state of design for his business.

The Jury was immediately impressed by the elegant, simple, clean, sophisticated, cool and ingenious design of Urband Origami. But perhaps even more, we were moved by Wah Kiang’s unique and profound sensibility toward materials and production craft, which is, more often than not, lost in the design industry today.

It is not surprising that Urband Origami has won other prestigious international design awards, including the red dot award for product design and the iF (International Forum Design Hannover) gold award, both in 2009.

VIEW JURORS

Nominator Citation

MS JULIE WANG

FINANCE MANAGER

NANYANG OPTICAL CO PTE LTD

The Urband Origami frame bears testimony to the ingenious application of the popular origami paper art to materials beyond paper. The innovation extends the origami art concept to metal to create a frame free of soldering, screws and hinges. Each fold of the origami frame is meticulously bent to ensure a balanced frame structure for a good fit.

The use of metal for frame construction proves to be challenging where accuracy and precision is critical at every bend of a thin metal sheet to create a frame that is both stylish and elegant.

The frame also applies the patented S-clip technology in place of screws to secure the frame front to the temples to allow springing movements of the temples for flexibility and wearing comfort.

Urband Origami aspires to be environmentally friendly with the use of recyclable materials such as stainless steel in the frame construction process, hence it is definitely worthy of an award nomination for Design of the Year 2009.