* DESIGN OF

THE YEAR 2020

AirMesh Pavilion

Designer

AirLab @ Singapore University of Technology & Design

Zhejiang University

DISCIPLINE

Engineering Design

Landscape Design

Systems Design

Digital Design

DESIGN IMPACT

Making Ground-breaking Achievements in Design

CONTACT

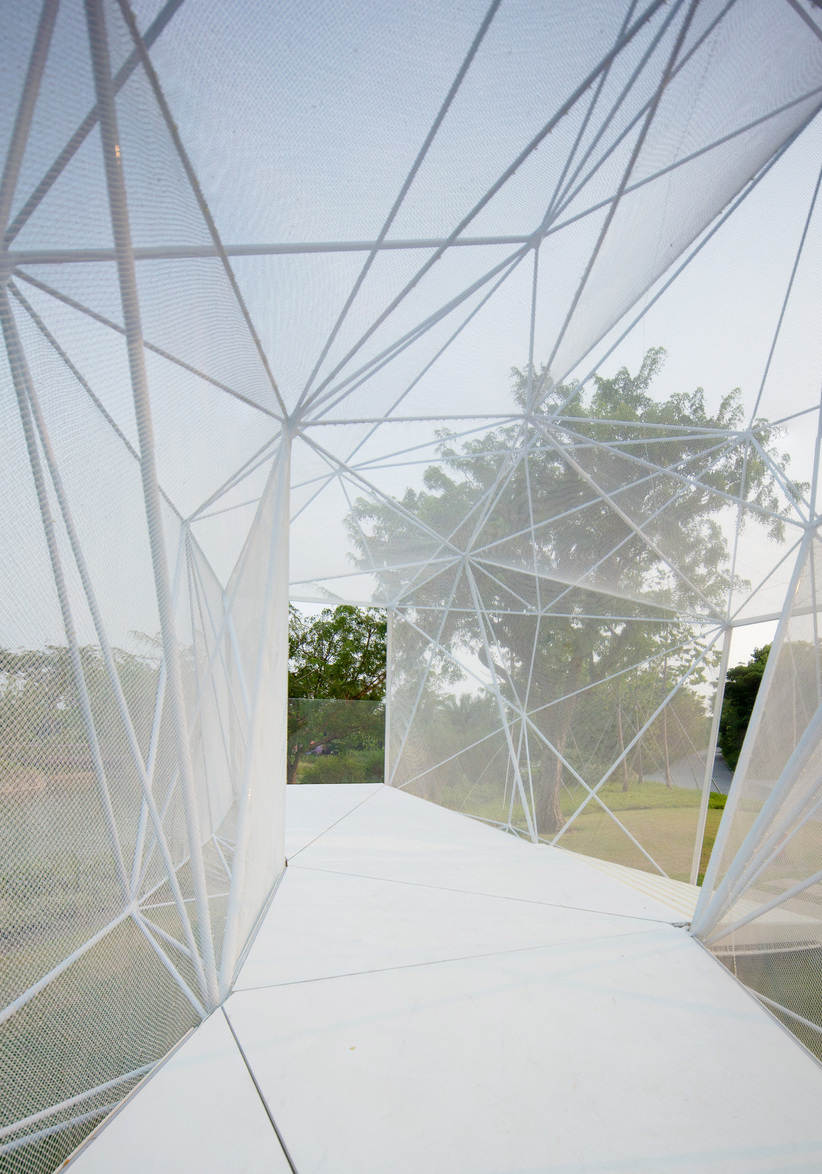

Sitting atop a grassy knoll at Gardens by the Bay, it lights up in the evenings like a gem. The AirMesh Pavilion is indeed a shining example of what construction in the future could be. It is one of the world’s first fully functional space frame structures made of 3D printed stainless steel components – a resounding proof of concept for a new construction system.

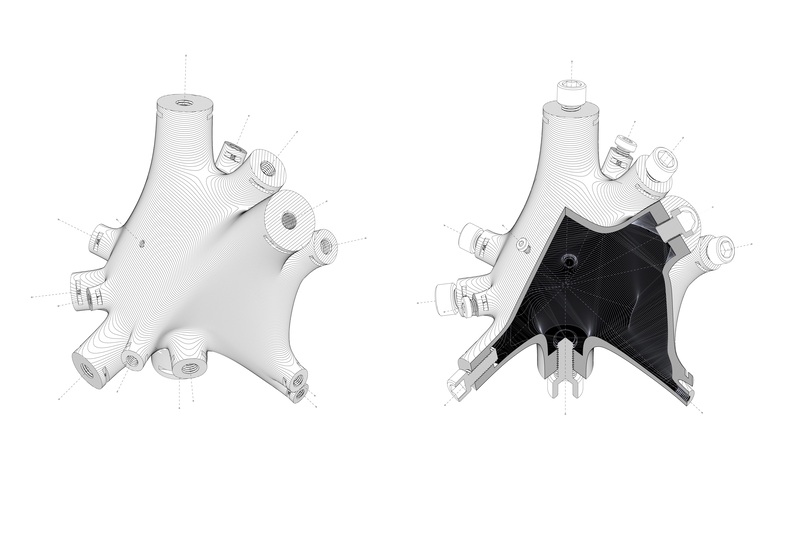

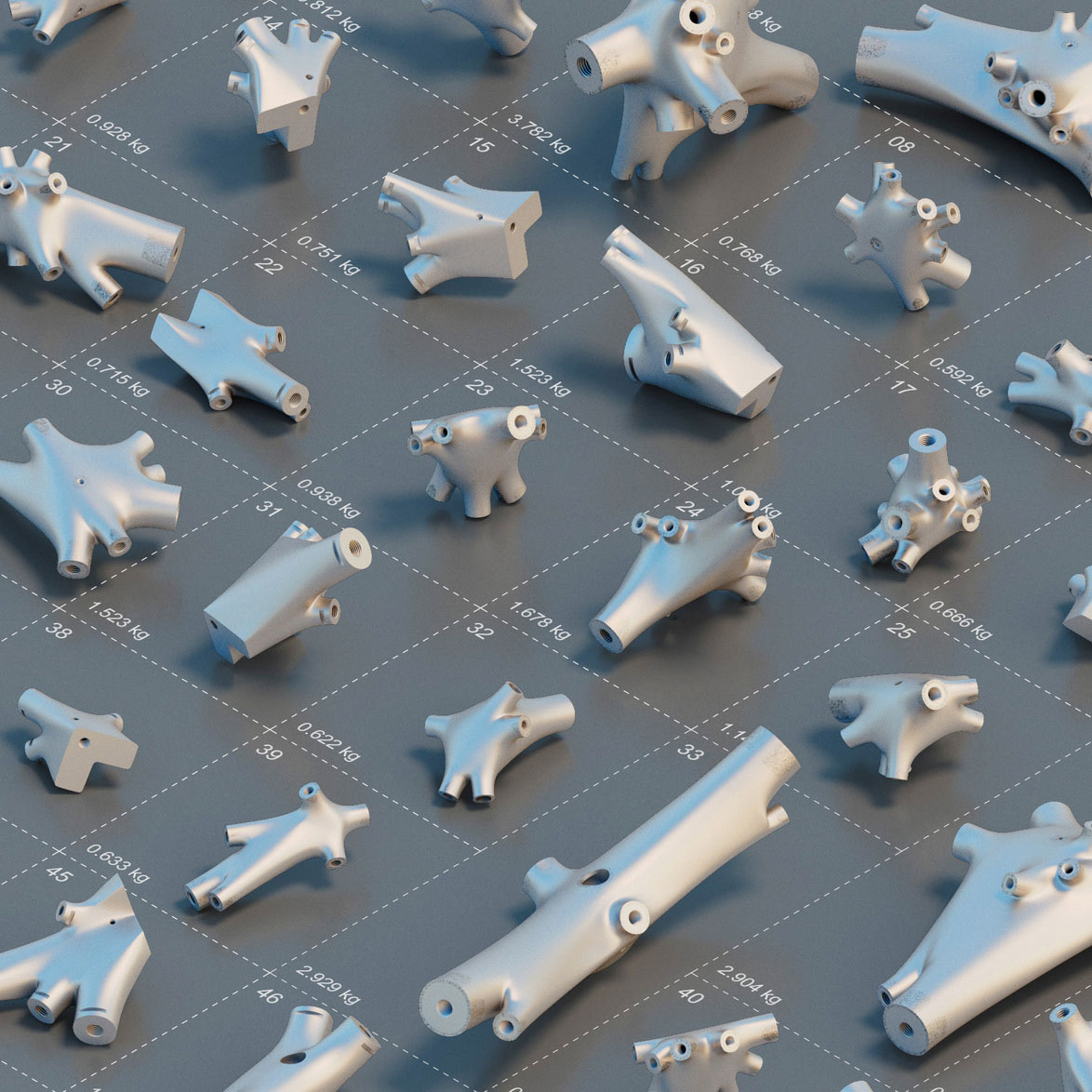

The technology disrupts traditional space frame structures that are limited by standardised nodes and bars. Instead, the pavilion’s complex design is made with 54 bespoke nodes and 216 bars of different lengths and sections to give the most optimal configuration and distribution of material. Such precise customisation was easily achieved with the completely digital workflow, and no materials were wasted as the nodes were manufactured with an additive 3D printing process. The parts were also designed for easy assembly to save construction time and the need for skilled manpower.

Despite such advanced origins, the AirMesh Pavilion’s understated design complements, rather than overpowers, its surrounding natural landscape. It is a model of how design can bring the built and natural environments together for a more sustainable tomorrow.

READ MOREABOUT THE DESIGNER

Founded in 2015 by Carlos Bañón and Felix Raspall, the Architectural Intelligence Research Lab (AirLab) is a multidisciplinary research laboratory focusing on architecture, science, arts, digital design, and manufacturing. It combines new technologies and digital manufacturing to create efficient, light, and versatile products that aim to increase sustainability and reduce wastage in construction.

The laboratory is established at the Singapore University of Technology and Design (SUTD). It is led by Carlos, an architect specialising in Digital Design processes and Advanced Manufacturing methods for the creation of more sustainable spaces and resource efficient products and spaces.

He is also the Co-founder of the award-winning architectural firm Subarquitectura, and an Assistant Professor of Architecture and Sustainable Design at SUTD. Carlos holds a Masters of Architecture from the University of Alicante, Spain. His work has been widely recognised and exhibited globally, such as in the Design Museum of London, and the Venice Biennale of Architecture, as part of the Spanish and Singapore Pavilions.

DESIGNER

AirLab @ Singapore University of Technology & Design

Zhejiang University

CLIENT

Gardens by the Bay

STRUCTURAL CONSULTANT

TCP Consultants Pte Ltd

Insights from the Recipient

Citation

Jury Citation

AirMesh Pavilion and the technology behind it put Singapore firmly at the forefront of global additive manufacturing of complex structures. The pavilion is an emphatic proof of concept and the first in the world to be made out of 3D printed stainless steel components.

Each of its bespoke joints was designed to receive as many as 25 individual elements in pure axial force. Its organic shape resembles the human heart in an eye-opening coincidence, pointing to the hypothesis that nature creates the most appropriate, efficient and desirable forms and shapes. As these joints are printed, it drastically reduces the use of materials and the entire structure’s embodied carbon footprint. It also allows for rapid deployment, such as the construction of dignified shelters for disaster relief.

The design’s overall congruence with nature helps to integrate the built and natural environments. It is an ambition that ought to be that of all designers. The Jury feels strongly that design innovations of this kind – with a strong ethos, sophisticated process, leading to an environmentally congruent product with significant impact –are deserving of recognition and a P*DA.

VIEW JURORSNominator Citation

Dr Toni Kotnik

Professor of Design of Structures

Aalto University, Helsinki

AirMesh Pavilion is a technological achievement that opens up new possibilities in architectural practice. Its creators were able to create a seamless and highly functional digital chain from design to fabrication by connecting and coordinating a set of software as well as 3D steel printing technologies. The interdisciplinary exchange of expertise has produced a new design tool for architecture.

It allows for the precise control of the flow of forces and allocation of material, resulting in a highly resource efficient structure of unprecedented lightness. The coherent workflow is robust and independent of scale, which makes the research applicable to a much larger building scale.

Besides a technologically advanced digital workflow and an efficient use of material, AirMesh Pavilion also demonstrates a new aesthetic of ephemeral construction. The radical aesthetic of nothingness may be seen as the future of sustainable design. It is a successful merger of design and technology, and has relevance far beyond Singapore.