DESIGN OF THE YEAR 2011

Dyson Digital Motor

Dyson, Singapore

When Dyson realised that the third-party motors for its appliances were limiting the development of its products, it decided to design its own motor.

“Conventional motors are big and bulky, so we couldn’t make our machines physically smaller or lighter,” explains Mr Low Yee Cheok, the leader of the Singapore motors team in this project. “Such motors were also inefficient, consuming a disproportionate amount of energy when compared to the output they generated.”

The Dyson team of over 50 engineers from both the United Kingdom and Singapore took a decade to design and develop the Dyson Digital Motor (DDM). This motor now powers several of its appliances, including its popular handheld vacuum cleaner, the DC34.

Unlike conventional motors, the DDM is halved in size as Dyson’s engineers have reduced the motor’s rotors by 50 per cent, making the rotating assembly weigh less than 100 grams. This smaller motor also provides twice the suction power when compared to a normal motor. Spinning at 1666 revolutions per second, the DDM is actually faster than a Formula 1 engine. As a whole, the DDM weighs 1000 grams compared to 1300 grams for a typical vacuum motor, giving it an excellent power-to-weight ratio.

Another feature of the DDM is its use of a strong electromagnetic field to generate the motor’s rotation, doing away with the need for carbon brushes. In conventional motors, these brushes are needed to maintain permanent contact with a closed electrical circuit for a motor to run. DDM’s design makes it more reliable and cleaner because it does not emit carbon particles and there is no contact to its rotor.

This motor was first conceptualised by Dyson’s engineers in the UK. After testing that it works, the company opened its first research and development facility in Singapore in 2007 and recruited a team to take the DDM from prototype stage to mass manufacturing. “Dyson chose to set up in Singapore because of the bright minds here,” says Mr Low. “Our production in Singapore is also geared towards high-precision, fully automated lines, which suited the production of the DDM.”

The engineers from the UK and Singapore worked together for three years to figure out how to mass manufacture the DDM. The Singapore team helped to optimise the design of the motor, create the setup for its manufacturing, as well as test the product.

“One of the biggest challenges faced was to design a machine that requires such high level of accuracy,” says Mr Low. Moreover, while motor parts are usually made from metal, Dyson chose to use plastic. “This created a challenge in itself as it is difficult to produce a motor which has plastic parts that can be glued in less than 30 seconds — a target time we set,” he says. In the end, the team specially created robots that could accurately align and glue the parts together to overcome this issue.

Mr Low attributes his team’s ability to design solutions for the various challenges they faced to the vast experience they have gained working in Singapore. “Singapore is a global city with many multinational corporations,” he says. “This gave me opportunities to be exposed to a variety of cutting-edge engineering environments, and has served me well in my work for Dyson.”

About the Designer

Research, design and development are the core of Dyson’s work. The company was founded by Sir James Dyson, who invented a variety of problem-solving products including the Sea Truck, a boat that can carry cargo to places with no jetty facilities, and the ‘ballbarrow’, a wheelbarrow with a ball in place of a wheel so it was less likely to get stuck in mud. He started Dyson after he created the world’s first bag-less vacuum cleaner, and the company continues its rich history of invention, holding over 1,900 patents and patent applications for over 300 different inventions as of July 2011.

With machines on sale in over 50 countries, Dyson has research, design and development facilities in the UK, Malaysia and Singapore that employ over 3,500 people worldwide. The Singapore centre was opened in 2007 to tap the country’s talent and its history of precision engineering. Currently, it has some 150 staff, and about two-thirds of them are engineers and designers who work on the development of Dyson’s non-floor care projects, including the Dyson Digital Motor, the next generation of its Air Multiplier blade-less fan, and its Air Blade hand dryer.

Dyson’s Singapore Motors Team Leader, Mr Low Yee Cheok has always had a fascination with how things work and began reading up books about this and building models since he was young. Eventually, he embarked on a career in various high-precision engineering environments in multi-national corporations before joining Dyson.

DESIGNER

Dyson, Singapore

Low Yee Cheok, Singapore Motors Team Leader

Dyson, UK

Andy Clothier, UK Motors Team Leader

Dyson, Singapore

Steve Organ, Head of Engineering

DESIGNER

Dyson, Singapore

Low Yee Cheok, Singapore Motors Team Leader

Dyson, UK

Andy Clothier, UK Motors Team Leader

Dyson, Singapore

Steve Organ, Head of Engineering

1DYSON DIGITAL MOTOR

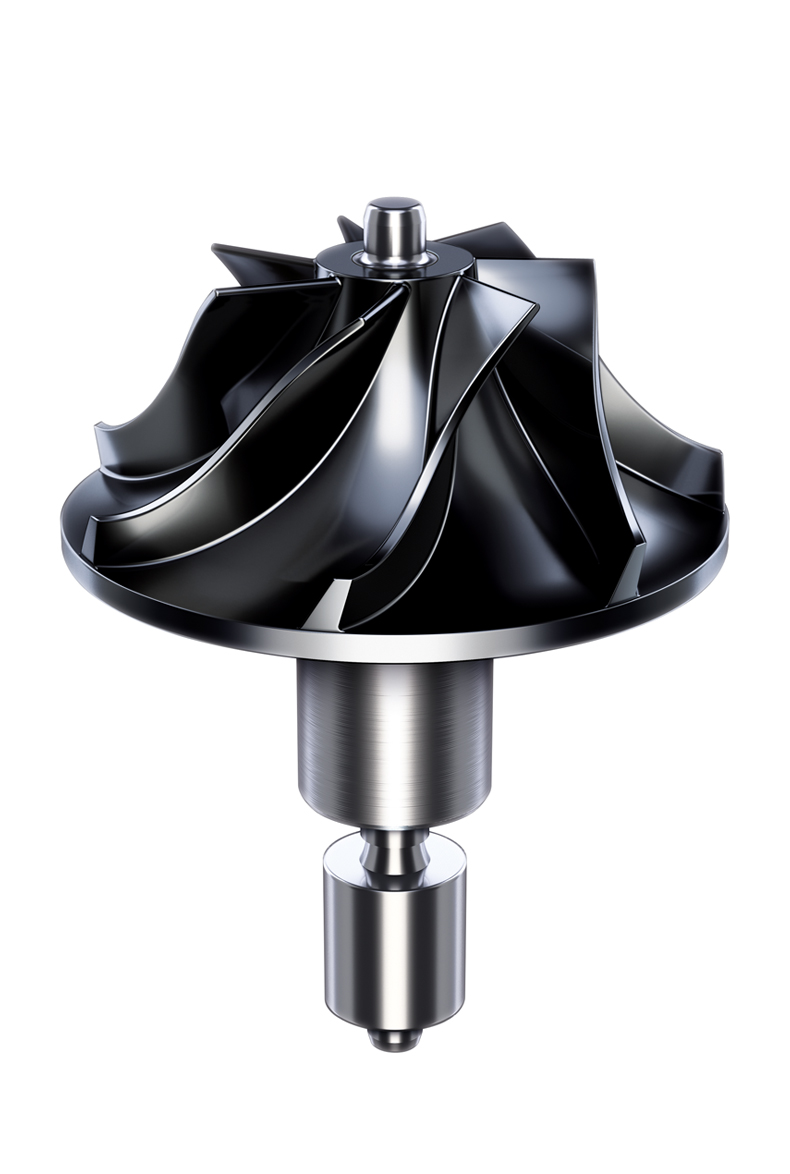

Beauty shot of DDM X020 Impeller

(Image by: Dyson)2DYSON DIGITAL MOTOR

Exploded view of DDM X020 at angle

(Image by: Dyson)3DYSON DIGITAL MOTOR

Beauty shot of DDM V2 Impeller with magnet

(Image by: Dyson)4DYSON DIGITAL MOTOR

Exploded view of DDM V2

(Image by: Dyson)5DYSON DIGITAL MOTOR

Dyson Airblade™ hand dryer showing exposed DDM

(Image by: Dyson)6DYSON DIGITAL MOTOR

DC31, a Dyson handheld vacuum cleaner showing exposed DDM which powers it

(Image by: Dyson)7DYSON DIGITAL MOTOR

DC31 Motorhead, a Dyson handheld vacuum cleaner with motorised brushbar showing exposed DDM which powers it

(Image by: Dyson)Insights from the Recipient

James Dyson: We wanted to create a new kind of motor that was efficient, light and durable. Conventional motors tend to be big and clumsy with copper windings and carbon brushes that wear out and need replacing. They create lots of heat and waste energy. Since the Dyson Digital Motor V2 won the Design of the Year award in 2011, our engineers have created a leaner and meaner machine. Using digital pulse technology, the V6 spins at up to 110,000 times a minute. It is small and power-efficient, weighing just 218 grams while generating 425 watts of power.

Citation

Jury Citation

Nominator Citation

AMELIA AUSTIN

COMMUNICATIONS MANAGER

DYSON, SINGAPORE

The Dyson Digital Motor, a single component within a larger entity, would not normally be considered for this award as it is entirely about brilliant design for manufacture.

However, the resolution is so competent that the Jury made an exception.

The Singapore-based engineering design office of UK manufacturer, Dyson, took the existing concept of a high-speed, digital motor/turbine assembly, and created a device that is way ahead of competitive components.

The considerable weight, material and volume reduction over its predecessor linked to a 30 per cent increase in turbine speed, and demonstrated ‘world-class’ Singapore core competences at work.

The Jury is refreshed by the presence of a ‘totally manufactured solution’ amongst a field of, generally, less resolved concepts and prototypes.

British physicist and chemist, Michael Faraday, discovered electromagnetic induction, the principle behind the electric motor, in 1831. While it was technologically advanced at the time, electric motors have changed very little since — they are bulky old-fashioned components with lots of moving parts that are prone to failure.

Dyson Digital Motor (DDM) was developed over nine years by a team of Singaporean and British mechanical, electrical, electronic, aeronautical, materials and software engineers. The DDM is much smaller, lighter, cleaner and more powerefficient than conventional electric motors.

Conventional alternating current (AC) motors use big fragile fans, copper windings and brushes that wear out easily, making them inefficient and unreliable. And as the carbon brushes wear down, they emit carbon particles, which is bad for the environment.

The DDM is 84 per cent energy efficient – and twice as efficient as its carbon brushed predecessor. With a power-to-weight ratio equal to that of a Ferrari sports car engine, it is the most powerful motor ever developed for home appliances. Though on a smaller scale, its development is comparable to the step change of the jet engine over the propeller in the aerospace industry.